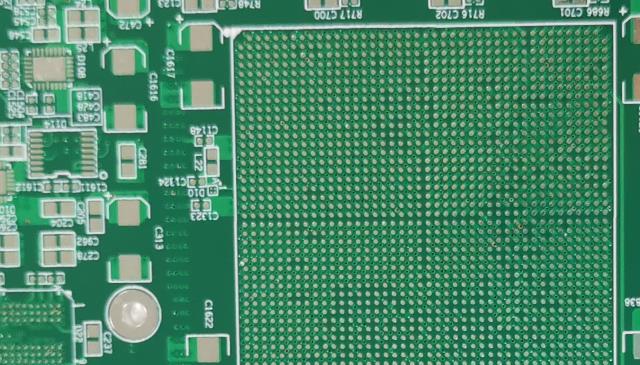

PCB Surface Treatment

PCB

surface treatment mainly includes: OSP, HAL, lead-free HAL, immersion gold,

immersion tin, immersion silver, hard gold plating, full board gold plating,

gold fingers, nickel palladium gold.

In

general, the common FR4 PCB surface treatments are as follows: gold plating

(electroplating gold, immersion gold), immersion tin, OSP, HAL (leaded and

lead-free). Different surface treatments have different advantages and

disadvantages.

OSP:

The cost is lower with good weldability and harsh storage conditions demands, the

time of storage is short. The process is environmentally friendly, and the

welding is smooth. When storing, need to pay attention to the environmental

temperature and humidity control.

HASL:

HASL board is generally 2-46 layers of high-precision PCB boards, which is

divided into two types, leaded and lead-free. Large-scale communications,

computers, medical equipment, and aerospace companies and research companies

will use it. When storing, also need to pay attention to the environmental

temperature and humidity control.

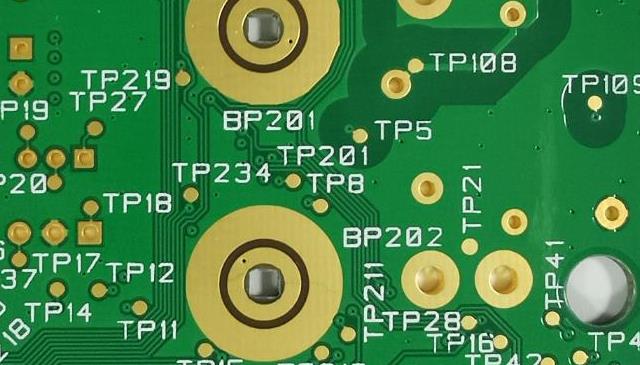

Gold

fingers: It is the connecting part between the memory bar and the memory slot,

and all signals are transmitted through golden fingers. The gold finger is

composed of many golden yellow conductive contacts. Because the surface is

gold-plated and the conductive contacts are arranged like fingers, it is called

"golden finger". The gold finger is actually coated with a layer of

gold on the copper clad board through a special process, because gold has

strong oxidation resistance and strong conductivity. However, due to the high

price of gold, most memories are now replaced by tin plating. Tin materials

have been popular since the 1990s. At present, the "golden fingers"

of motherboards, memory and graphics cards are almost all made of tin. Only

part of the contact points of high-performance servers or workstations will be

gold-plated.

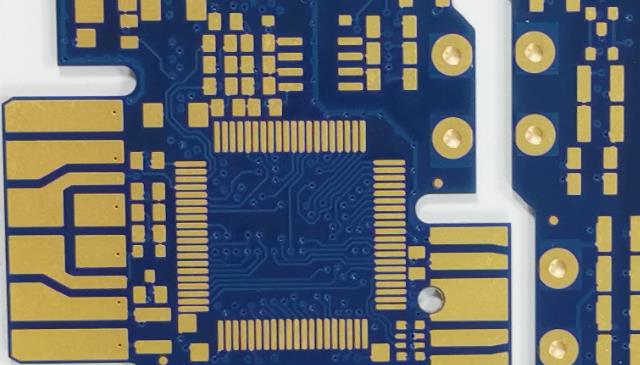

Gold

plating: The gold plating process include two types: electroplating gold and

immersion gold. In terms of tinning effect, the tinning effect of immersion

gold is better than electroplating gold. Unless the manufacturer requires

bonding, most manufacturers will now choose the immersion gold. Gold plating

allows PCB to be stored for a longer period of time, and is subject to small

changes in the external environment or temperature and humidity (compared to

other surface treatments). Generally, it can be stored for about one year.

Electroplating gold: As the integration level of IC becomes higher and higher, IC pins become more denser. The vertical spray tin process is difficult to flatten the thin pads, which brings difficulty to SMT; in addition, the shelf life of HASL is very short. The Electroplating gold just solves these problems: 1. For the surface mount process, especially for 0603 and 0402 ultra-small surface mounts, because the flatness of the pad is directly related to the quality of the solder paste printing process, and the quality of the subsequent reflow soldering Play a decisive influence, so the whole board gold plating is very common in high-density and ultra-small surface mount processes. 2. At the trial production stage, due to factors such as the purchase of components, it often takes a few weeks or even more than a month to use PCB board. The shelf life of the gold-plated board is many times longer than lead-tin alloy, so electroplating gold is welcome to be adopted. Besides, the cost of gold-plated PCB in the sample stage is almost the same as HASL board. However, as the wiring becomes denser, the line width and spacing have been reduced to 3-4 mil. Therefore, the problem of gold wire short circuit comes: as the frequency of the signal becomes higher and higher, the signal transmission in the multi-plated layer caused by the skin effect has more obvious influence on the signal quality. The skin effect refers to: high frequency alternating current, the current will tend to concentrate on the surface of the wire to flow. According to calculations, skin depth is related to frequency.

Immersion gold: In order to solve the problem of gold-plated PCB, the main features of immersion gold PCB are as follows: 1. Because the crystal structure formed by immersion gold and electroplating gold is different, immersion gold will be golden yellow, which is more yellow than electroplating gold, and customers are more satisfied. 2. Because the crystal structure formed by immersion gold and electroplating gold is different, immersion gold is easier to weld than gold plating, and will not cause poor welding lead to customer complaints. 3. Because the immersion gold board only has nickel and gold on the pad, the signal transmission in the skin effect is on the copper layer, which will not affect the signal. 4. Because immersion gold has denser crystal structure than electroplating gold, it is not easy to be oxidized. 5. Because the immersion gold board only has nickel and gold on the pads, it will not cause gold wires and lead to short circuit. 6. Because there is only nickel and gold on the pad, the solder mask on the circuit and the copper layer are more firmly combined. 7. The compensation will not affect the distance. 8. Because the crystal structure formed by immersion gold and electroplating gold is different, the stress of the immersion gold plate is easier to be controlled, which is more conducive to bonding processing. But at the same time, because the immersion gold is softer than electroplating gold, the immersion gold plate is not wear-resistant as gold finger. 9. The flatness and stand-by life of the immersion gold is as good as electroplating gold.

The

customer can choose the appropriate surface treatment according to the

advantages and disadvantages of the above different surface treatments and

their own product needs. High Precision Technology (HK) Co.,Ltd as a PCB manufacturer with more than 10

years of rich experience, all these common surface treatment processes can be

provided. Welcome to send us email for consultation info@gjzpcb.com