The manufacturing method of multi-layer circuit boards, generally to make the inner layer pattern plating first, and then make the single-sided or double-sided substrate by printing and etching, and incorporate it into the specified layer, and then heat, press and glue it, and then other produce process is same as the production of double layer panel. In terms of performance, multilayer circuit boards are better than single and double layer circuit boards. However, the higher count of layers, the more of production cost. And the manufacturing time is longer and requires more reliable detection methods.

Compared with single and double-layer circuit boards, the advantages of multilayer circuit boards: 1. The assembly density of multilayer circuit boards is high and the volume is small. 2. The multi-layer circuit board is convenient for wiring, and the wiring length and the connection between components are shortened, which is beneficial to increase the speed of signal transmission. 3. For high-frequency circuits, after adding the ground layer, the signal line will form a constant low impedance to the ground layer, the circuit impedance is greatly reduced, and the shielding effect is better. 4. For electronic products with high heat dissipation requirements, multilayer circuit boards can be equipped with a metal core heat dissipation layer to meet the needs of special functions such as shielding and heat dissipation.

Multilayer circuit boards have been widely used in the manufacture of electronic products due to their design flexibility, economic superiority, stable electrical performance and reliability.And now it is widely used for electronic products manufacturing.

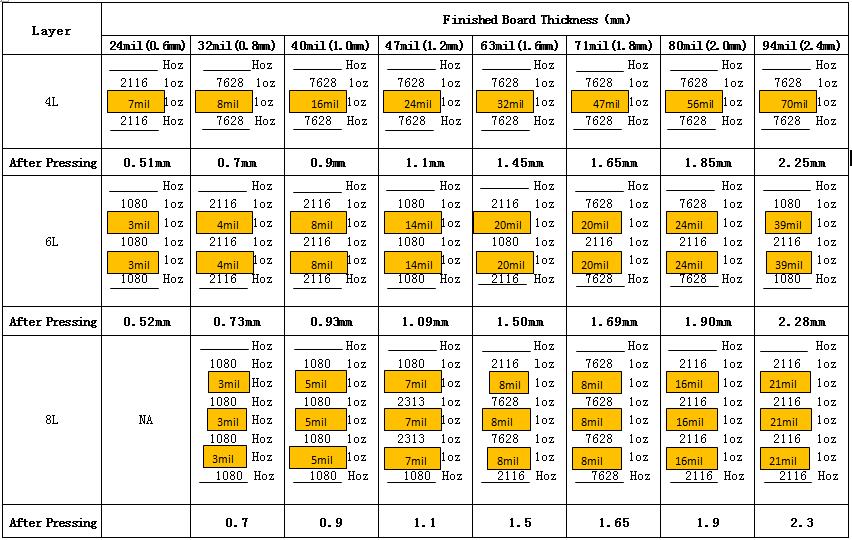

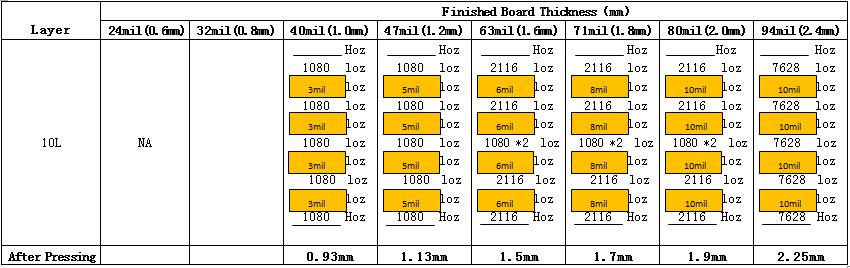

High Precision Technology (HK) Co.,ltd, as a printed circuit board manufacturer,the following stackup is standard version in our manufacturing for your reference.And we also accept custom version if you have.

Welcome to send us email for more details. info@gjzpcb.com