Why are most PCB board green?

Nov 04, 2021

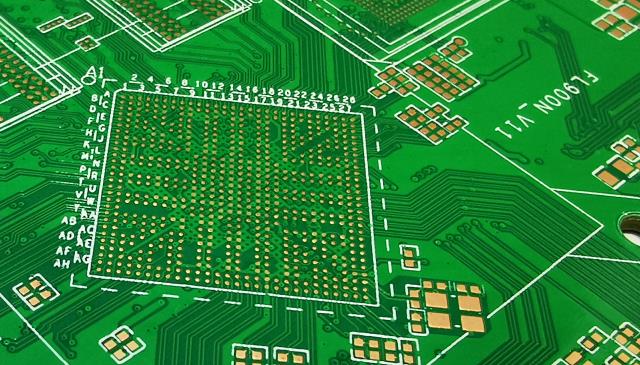

Solder Mask

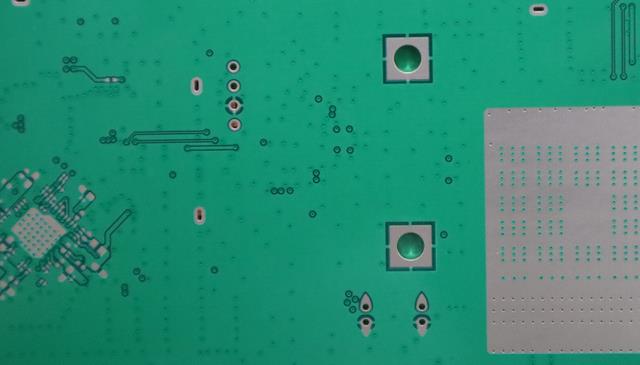

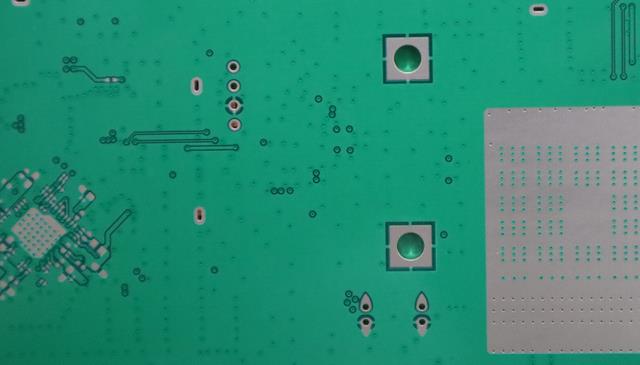

Both sides of the PCB are copper layers. In PCB production, the final copper layer is a smooth and unprotected surface. Although the chemical properties of copper are not as active as aluminum, iron, magnesium, etc., pure copper is easily oxidized when there’s water and oxygen. Because of the presence of oxygen and water vapor in the air, the surface of the pure copper will oxidize very quickly after contact with air. Since the thickness of the copper layer in the PCB is very thin, the oxidized copper will become a poor conductor of electricity, which will greatly impair the electrical performance of the entire PCB.

To prevent oxidation of copper, and also to separate the welded and non-welded parts of the PCB during soldering, and to protect the surface of the PCB, engineers invented a special coating. This coating can be easily to be mounted on the surface of the PCB to form a protective layer with a certain thickness and to block copper and air contact. This layer of coating is called as solder mask and the material used is solder resist.

Why are most PCB board green?

1.Green solder mask oil is the oldest and most cost effective, and the most widely used. Early printed circuit boards (PCB) only has one or two sides, these sides are yellow which is the original color of the laminate material. Later, the typical multilayer printed circuit boards (PCB) replaced these boards and were with green solder mask for a long time.

Why are most PCB board green?

1.Green solder mask oil is the oldest and most cost effective, and the most widely used. Early printed circuit boards (PCB) only has one or two sides, these sides are yellow which is the original color of the laminate material. Later, the typical multilayer printed circuit boards (PCB) replaced these boards and were with green solder mask for a long time.

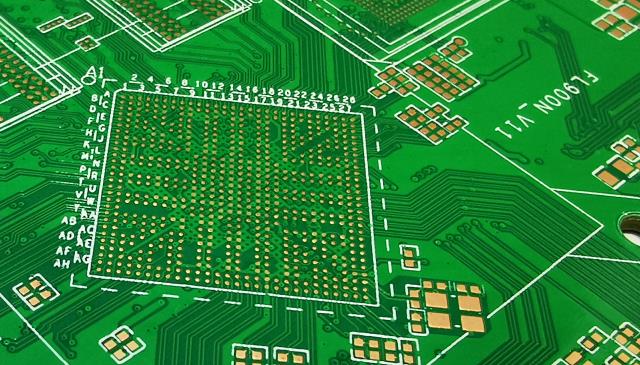

2.Generally speaking, all PCB need to go through PCB manufacturing flow and assembly process, and there are several processes in PCB manufacturing process flow is to go through the yellow light, visual effect is better for green in the yellow light room. But this is not the main reason. In SMT soldering, pcb needs to go through the tin and SMD and the final AOI verification, these processes all need to be calibrated through the optical positioning.The instrument has a better effect on the recognition of green background color.

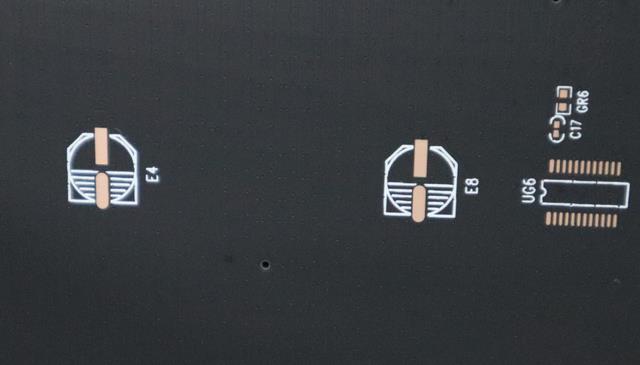

3.In the process of printed circuit board manufacturing, after e-testing, every pcb need to be inspected by worker again,and workers have to stare at the pcb with the naked eye for a long time to check. Green is relatively less irritating to the eyes and less prone to eye fatigue. So most designs use green solder mask.

4.The common solder mask colors are red, yellow, green, blue, and black. Most prominently, commercial green solder mask is the only available color that can reliably produce solder mask dams of 0.1mm. The most prominent factor of choosing green solder mask is that it is the only available color that can reliably produce solder mask dams of only 0.1mm. Next up is red, yellow and blue that can produce 0.12mm dams and then black and white which can typically only achieve 0.15mm. Solder mask dams are vital for ICs and fine pitch components since they are valuable in preventing solder bridges from forming. And white is more picky and prone to obvious defects of insufficient coverage or depth. In the process of cleaning PCBs, black is the most likely to cause color differences, and if the PCB factory uses raw materials and production processes are slightly deviated, it will cause an increase in the rate of PCB defects because of color differences. This directly leads to an increase in production costs.

High Precision Technology specialises on PCB manufacturing for more than 10 years.Welcome to send us inquiry for more details.info@gjzpcb.com